Quick Details

Place of Origin: Shandong, China, QINGDAO,SHANDONG

Brand Name: FRT

Model Number: 9580270

Size: D50=10-25

Type: Artificial

Application: Industrial production and battery, Chemical industry

Shape: Expandable/Dilatable Graphite Powder

Carbon Content: HIGH-CARBON, 99%

Product name: expanded graphite

Expansion Rate: 270

Appearance: Black Power

PH Value: 3-8

Product Parameter

|

Variety |

Moisture(%) |

Carbon content(%) |

Sulfur content(%) |

Expansion temperature(℃) |

|

Ordinary |

≤1 |

90--99. |

≤2.5 |

190--950 |

|

Superfine |

≤1 |

90--98. |

≤2.5 |

180--950 |

|

Low sulfur |

≤1 |

90--99. |

≤0.02 |

200--950 |

|

High purity |

≤1 |

≥99.9 |

≤2.5 |

200--950 |

Application

Expanded graphite manufacturers can be treated into flexible graphite as a sealing material. Compared with traditional sealing materials, flexible graphite can be used in a wide temperature range, in the air range of -200℃-450℃, and thermal expansion coefficient is small, has been widely used in petrochemical, machinery, metallurgy, atomic energy and other industries.

Expanded graphite is widely used, and the main development directions are as follows:

1, particle expanded graphite: small particle expanded graphite mainly refers to 300 purposes of expandable graphite, its expansion volume is 100ml/g, the product is mainly used for flame retardant coating, its demand is great.

2, high initial expansion temperature of expanded graphite: the initial expansion temperature is 290-300℃, expansion volume ≥230ml/g, this kind of expanded graphite is mainly used for engineering plastics and rubber flame retardant.

3, low initial expansion temperature, low temperature expansion graphite: this kind of expansion graphite begins to expand at 80-150℃, 600℃ expansion volume up to 250ml/g.

Production Process

1.The initial raw material for chemical intercalation is high carbon flake graphite

2.Electrochemical method

3. Ultrasonic oxidation method

4.Gas phase diffusion method

5, molten salt method

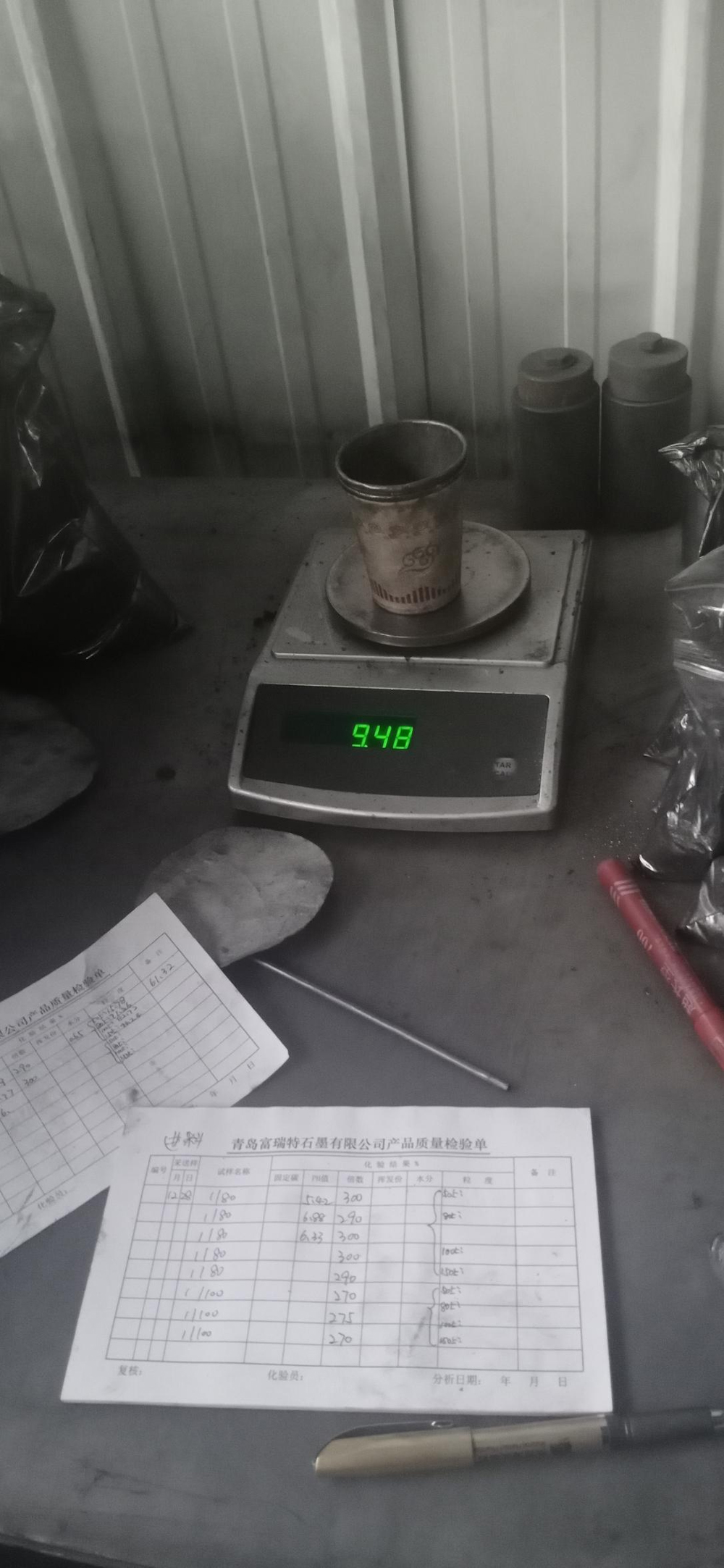

Quality control

FAQ

Q1. What is your main product?

We mainly produce high purity flake graphite powder,expandable graphite ,graphite foil ,and other graphite products. We can offer customized according to customer's specific demand.

Q2: Are you a factory or trading company?

We're factory and has the independent right of export and import.

Q3. Can you offer free samples?

Usually we can offer samples for 500g, if the sample is expensive, clients will pay the basic cost of the sample. We do not pay the freight for the samples.

Q4. Do you accept OEM or ODM orders?

Sure, we do.

Q5. How about your delivery time?

Usually our manufacture time is 7-10 days. And meanwhile it takes 7-30 days to apply the Import and export license for dual-useitems and technologies, so the delivery time is 7 to 30 days after payment.

Q6. What is your MOQ?

There is no limit for MOQ, 1 ton is also available.

Q7. What is the package like?

25kg/bag packing,1000kg/jumbo bag, and we pack goods as customer's requested.

Q8: What is your terms of payment?

Usually, we accept T/T, Paypal, Western Union.

Q9: How about transportation?

Usually we use express as DHL, FEDEX, UPS, TNT, air and sea transportation is supported. We always choose economist way for you.

Q10. Do you have after-sale service?

Yes. Our after-sales staff will always stand by you, if you have any questions about the products, please e-mail to us, we will try our best to solve your problem.

Product Video

Advantages

① Strong pressure resistance, flexibility, plasticity and self-lubrication;

② Strong resistance to high, low temperature, corrosion resistance, radiation resistance;

③ Strong seismic characteristics;

④ Strong electrical conductivity;

⑤ Strong anti-aging and anti-distortion properties;

⑥ Can resist the melting and penetration of various metals;

⑦ Non-toxic, does not contain any carcinogens, no harm to the environment;

Packaging & Delivery

Lead Time:

| Quantity(Kilograms) | 1 - 10000 | >10000 |

| Est. Time(days) | 15 | To be negotiated |

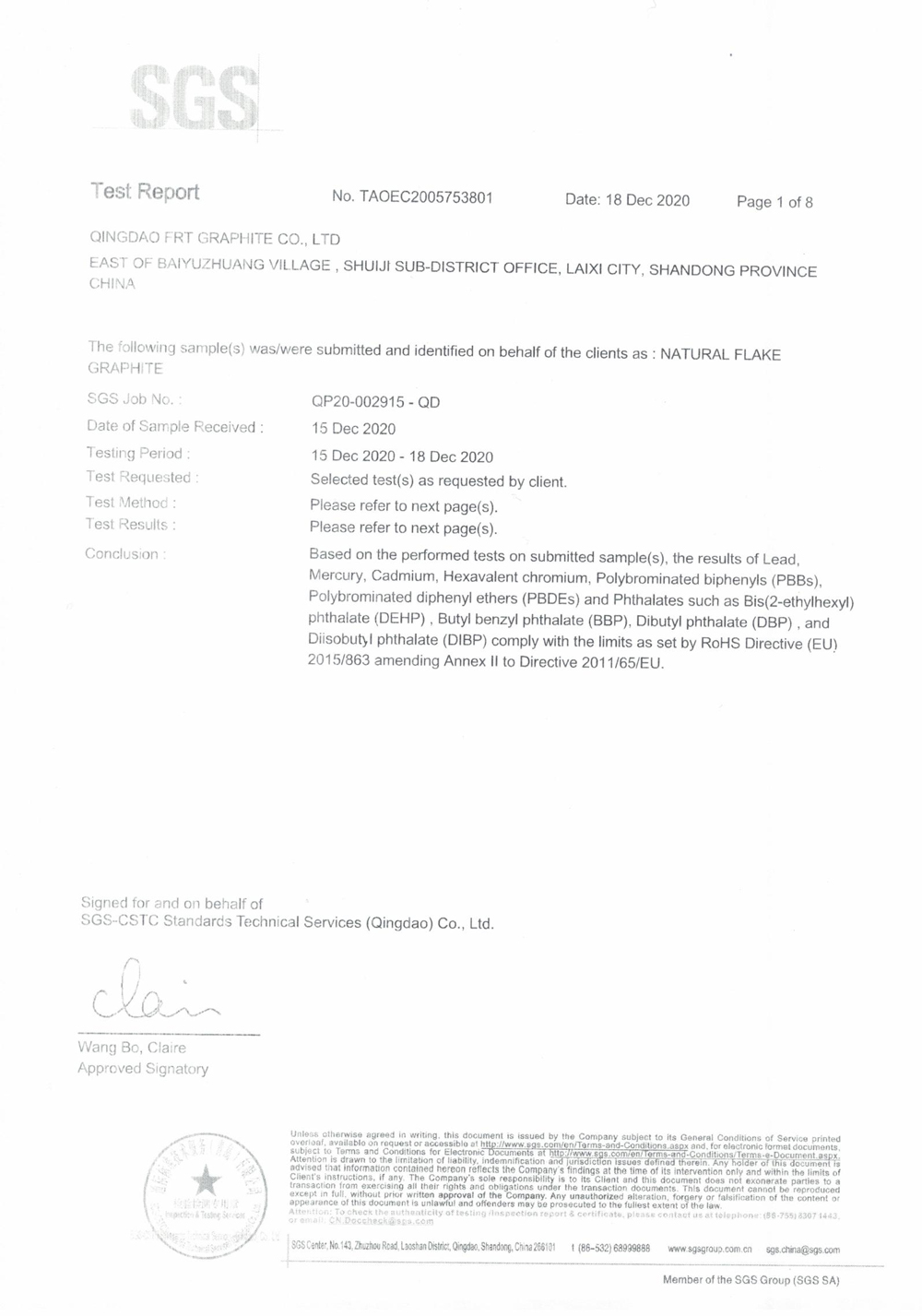

Certificate