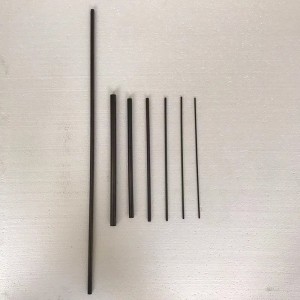

Product Properties

Brand: FRT

Origin: China

Specifications: 600 * 500 * 1150mm 650 * 330 * 500 mm

Applications: metallurgy/petrochemical/machinery/electronics/nuclear/national defense

Density: 1.75-2.3 (g/cm3)

Mohs hardness: 60-167

Color: black

Compressive strength: 145Mpa

Process customization: Yes

Product Usage

Moulds for glass forming

Because stone graphite material with chemical stability, susceptible to infiltration of molten glass, will not change the composition of the glass, graphite material thermal shock performance is good, the characteristics of small size change with temperature, so in recent years become indispensable in the glass manufacturing mold material, it can be used to manufacture glass tube, pipe, funnel and other forms of special shape of glass bottle mould.

Production Process

Graphite raw material is cut to get graphite mold blank; Grinding steps, grinding the outer surface of the graphite mold blank, get the blank fine grinding pieces; Clamping leveling step, the blank fine grinding parts are installed on the fixture, and the blank fine grinding parts on the fixture leveling; Milling steps, a CNC milling machine is used to milling the blank fine grinding parts clamped on the fixture, and the semi-finished graphite mold is obtained; Polishing steps, the semi-finished product of the graphite mold is polished to obtain the graphite mold.

Product Video

Packaging & Delivery

Lead Time:

| Quantity(Kilograms) | 1 - 10000 | >10000 |

| Est. Time(days) | 15 | To be negotiated |